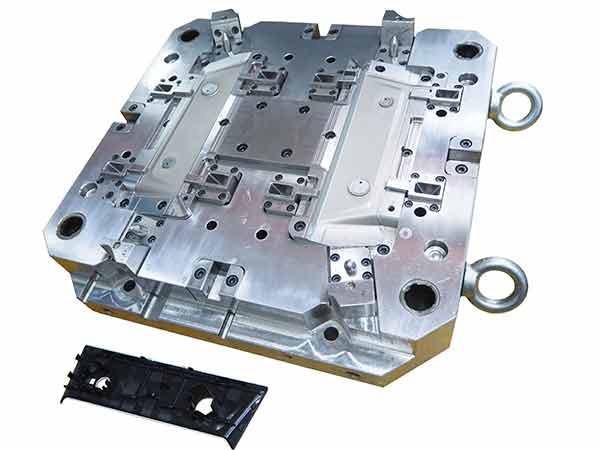

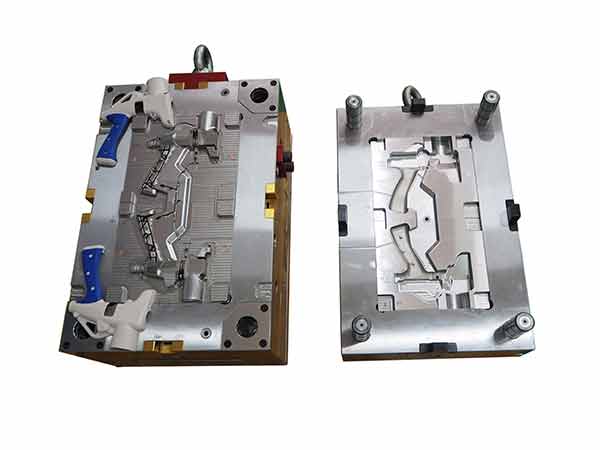

Mold Making

Plastic injection mold design and manufacturing. We provide customers with high quality plastic molds and competitive prices,fast delivery and intimate service. Our aim is to establish long-term cooperative relationship with each customer.

Through the last 18 years developing, HotTop have built several long-term business relationship with European and American customers. Our project management is mature and strict, schedule status reports are provided either by email, team conference calls, or both as per our client's requirements.

1. Mold weekly progress report.

2. Mold trial report and video.

3. Steel and sample dimension measurement report.

4. Mold base, steel, hot runner, heat treatment certifications, etc .

- Conformal Cooling

- Performance Alloys

- Servo Driven Mold Action

- Ultra-Complex/Actions

- Servo/Plate Drive Valve Gate

- High Cavitation (fully interchangeable)

- -In

- 2-shot- Robotic, Rotary, Core Back, etc.

- Stack Tooling

Our hunger for innovation leads to investments in our facility and people that allow us to tackle 1-2MM tooling programs successfully.

CNC: Best-in-class machines f-rom Yasda, Makino, Roders, and Mazak are used to provide accurate, repeatable results. Graphite machining cell includes 3R robotics for true 24/7 machining capacity.

EDM/WEDM: Five sinkers f-rom Mitsubishi sit adjacent to three Fanuc Wire EDMs. 3R Robotics in EDM cell are also used for true 24/7 manufacturing capability.

Polishing and Laser Welding: Extreme remains committed to a strong internal department who compliments our outside polishing specialists. Rofin Laser Welder allows us to repair or revise your molds quickly, accurately and within our complete control.

Finishing: Our toolmaking specialists use best-in-class grinding equipment f-rom Mitsui and Okamoto to complete the most critical operations on our molds. These machines are built to hold tenths, and there is no room for accuracy degradation on the last steps of mold manufacturing.

Mold Quality Control: Our OGP machine offers touch, laser and vision capability all within one machine. Detailed inspection reports are provided for critical areas of all injection molds we build. Brown and Sharp CMM is used to inspect every electrode we manufacture, before it is approved for use by our EDM dept.

Proven Results. No Excuses.

Proven Results. No Excuses.